Lesson Learned: Electrical Near-Miss

Quick Summary

- Water spills on a power strip, resulting in a shock

Describe the incident:

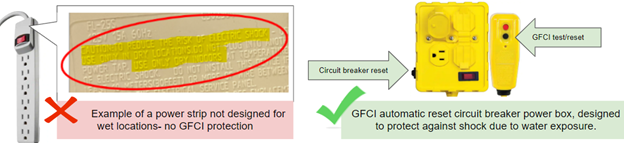

An individual was removing unplugged equipment from a fish tank that was being disassembled. Please note there were no fish in the tank. It is believed that water from the filter being removed, spilled on a power strip that had other equipment plugged into it. The individual felt a tingling sensation in the hand and arm. The department noticed the power strip had arced. The power strip was not designed for wet environments and did not have ground fault circuit interrupter (GFCI) protection.

Upon inspection, it was determined that the outlets receptacles were not GFCI protected. The department thought that the room may have had GFCI built into the electrical system as it was designed for their research. Upon inspection by qualified electricians, it was discovered that there was no GFCI protection in the circuit breakers at the electrical panel.

What went right?

- The department ensured immediate medical care and reported the accident through the proper channels, by filling out the Employers First Report of Injury .

- The department gathered the initial facts of the accident including which pieces of electrical utilization equipment were involved in the accident. They removed the equipment from service and retained it so it could be inspected as part of the EH&S accident investigation.

- Due to a recommendation made during an inspection by an outside agency prior to the accident, the lab had purchased power boxes with GFCI protection with an internal circuit breaker that were designed for use in wet locations. However, they didn’t purchase enough of the power boxes so they were using some power strips that were not designed for wet locations, including the one involved in the accident.

What should have been done differently?

Contributing causes:

- The department believed that GFCI protection was built into the electrical system for the room, but this was not confirmed prior to the accident. After an inspection by qualified electricians as part of the accident investigation, it was determined that the electrical system is not GFCI-protected at the panel or through the outlet receptacles. Per the consultation from the Building Maintenance Service’s qualified electricians there were three options to provide protection in this wet location. Please note the room was designed with the outlet receptacles above head height, options may vary per exposure and room design:

- Install GFCI-protected circuit breakers at the panel.

- Replace all receptacles in the room with GFCI-protected receptacles.

- Ensure every receptacle in the room has a power strip with GFCI protection and internal circuit breakers designed for wet environments like the Tower Model 30434052 Quad Outlet Boxes.

- The department attempted to use distance as means of protection against electrical shock exposures in a wet environment by Velcroing the power strip to the wall. While this was an attempt to reduce the risk of electrical shock, it did not provide adequate protection. The power strip was not designed to be used in a wet environment. Equipment used in this room should be designed for use in a wet environment.

Root cause:

- The department had not completed a hazard assessment to determine if adequate controls were in place to protect against electrical shock in a wet environment.

- The department does not have a purchasing process that ensures equipment selected for use in this room is designed for wet environments.

How to prevent this in the future:

- Remove all equipment from service that was involved in the accident as it may be compromised. Dispose of equipment to ensure it is not accidentally brought back into service.

- In this case it was determined that every receptacle in the room will have has a power strip designed for wet locations with GFCI protection and internal circuit breakers. This was reviewed by Building Maintenance Services Electrical Shop and Fire Prevention for approval.

- Create a purchasing process to ensure power strips and other electrical utilization equipment brought into this room are designed for wet environments.

- Conduct monthly checks to ensure the Tower Model 30434052 GFCIs on the Quad Outlet Boxes are working as they are not self-checking.

Questions about this Lesson Learned? Contact shopsafety@ucdavis.edu